Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Galvanized Steel Coil

The zinc coating acts as a barrier between the steel and its surroundings, preventing rust and corrosion from forming on the steel’s surface. It serves as a sacrificial layer, which means that if the coating is broken or scratched, the zinc corrodes before the underlying steel.

Description

SZ DEPU METALS: Your Professional Galvanized Steel Coil Supplier

Shenzhen Depu Technology Co., Ltd. located in Xi'an High- tech Zone, Shaanxi, China, has been in business for over 30 years and is a professional manufacturer integrating R&D, production, sales and service. We are the leading provider of stainless steel sheets, coils, strips, tubes, bars, and custom stainless steel products and also specialized in the production and sales of galvanized wire, galvanized pipe, galvanized color-coated corrugated sheet and other products, which are widely used in construction, transportation, chemical industry and light industry.

Why Choose Us?

Extensive Inventory

With a vast stock holding of galvanized wire, galvanized pipe, aluminum products, stainless steel sheets, coils, strips, tubes, and bars, we have a wide range of products readily available to meet your immediate needs. Our comprehensive inventory ensures quick access to the materials you need.

High Quality

We only use the finest raw materials and have a rigorous quality control process in place. The products can meet the national standards, American standards, European standards and other foreign standards to meet the special technical needs of different customers. We've been awarded third-party certifications including ISO 9001-2015 and EN-1090-2. These absolutely verify our technical expertise and confirm that we meet the standards set by regulatory authorities.

Professional Team

We have more than 300 technical personnel, and the design engineers have more than 25 years of experience in designing and building molds that offer innovative solutions to complex design challenges. Our state-of-the-art equipment and skilled technicians offer laser cutting, plasma cutting, waterjet cutting and more, guaranteeing precise dimensions, clean finishes and no additional processing required.

Superior Service and Logistics

Our customer team is highly skilled, motivated and always ready. No matter you are following up on an order, looking for advice or seeking a bespoke quotation, our team is here to help. We partner with reliable logistics providers to offer secure and timely delivery. Our team handles all customs clearance, documentation, and transportation complexities to ensure your stainless steel arrives safely and efficiently.

Corrugated Galvanized Steel Roofing Sheet

Corrugated galvanized steel sheets are a popular choice for various construction and industrial applications due to their durability, resistance to corrosion, and affordability. The surface is galvanized to improve its corrosion resistance and durability. Its corrugated shape not only enhances its structural strength, but also helps with drainage and reduces the impact of wind and snow on the roof.

PPGI PPGL Prepainted Steel Coil

PPGI stands for Pre-Painted Galvanized Iron. It is also known as pre-painted galvanized steel or color coated steel. These surfaces undergo treatment through methods like spray painting, powder coating, or electroplating and ensures long-lasting protection, guarding against rust, weather damage, and fire hazards to meet your requirements effectively.

Galvanized square tubes are mainly made of ordinary carbon steel materials, and the outer surface is galvanized to improve its corrosion resistance. The cross-sectional shape of the galvanized square tube is square, and the four corners are exactly equal.

Household aluminum foil is a common and versatile cooking and food preservation equipment in modern homes. Because it has a good barrier effect, common aluminum foil can keep moisture out, preserve food flavor, stop moisture loss, and keep food fresh for a very long period.

Aluminium foil is a thin sheet of metal foil comprising about 92-99% aluminum. Its thickness is typically between 0.0002 to 0.006 inches. Its width and intensity are very different due to expected applications. It is a material that is durable, non-toxic, and oil-proof, which can resist chemical erosion.

Copper foil is a thin sheet of copper metal that is widely used in various applications due to its excellent electrical conductivity, malleability, and corrosion resistance. It is an essential material in the electronics industry, especially for manufacturing printed circuit boards (PCBs) and other electronic components.

431 stainless steel is a type of martensitic stainless steel with high chromium content and moderate nickel content. It is commonly used in applications that require good corrosion resistance, high toughness, and high tensile strength. The high strength and corrosion resistance of 431 stainless steel make it suitable for use in harsh environments such as marine and chemical processing industries.

201 stainless steel coil is a type of stainless steel that is often used in various applications due to its excellent corrosion resistance and high strength-to-weight ratio. It is also relatively inexpensive compared to other stainless steel grades, making it a popular choice for many industries.

Marine stainless steel tubing is a type of tubing made from stainless steel that is suitable for use in marine environments. Marine stainless steel tubing is commonly used in a variety of applications, such as boat rails, bimini tops, and other marine hardware. It is also used in industrial applications, such as oil and gas processing and chemical processing, where corrosion resistance is important.

Benefits of Galvanized Steel Coil

Good Weather Resistance

The zinc layer on the surface of galvanized steel coils has good weather resistance and can resist the erosion of sunlight, rain, wind and snow and other natural environments, ensuring its service life for decades. In addition, the reflection of ultraviolet rays from galvanized steel coils can also lower the temperature of the building, reduce the use of air conditioners, and achieve the effect of energy saving and emission reduction.

Easy to Process and Install

Galvanized steel coils have good processing properties and can be easily processed into various shapes through shearing, bending, forming and other processes. At the same time, the installation of galvanized steel coils is also very convenient and can be used in conjunction with other materials, improving construction efficiency.

Good Environmental Performance

During the production process, galvanized steel coils do not produce harmful gases and cause less environmental pollution. In addition, it has good recyclability and can be reused to reduce resource waste.

Longevity

Galvanized steel coil's exceptional durability translates to extended lifespans for various products, from buildings to vehicles, resulting in cost savings over time.

Low Maintenance/Lowest Long-term Cost

Even though the initial cost of galvanizing is higher than alternative coatings, galvanizing is almost always cheapest in the long run (because it lasts longer and requires less maintenance). The zinc coating on galvanized steel acts as a protective barrier, preventing the underlying steel from rust and corrosion. This resistance extends the lifespan of materials, reducing maintenance and replacement costs.

Aesthetic Appeal

Galvanized steel's metallic appearance contributes to the aesthetic appeal of products, making it suitable for both functional and design-oriented applications.

Versatility

Galvanized steel coil can be customized for different applications, thanks to its wide range of available coatings and thicknesses.

Utilization of Galvanized Steel Coil

Construction

Galvanized steel coils are widely utilized in the building industry. They are used to make roofing materials such corrugated sheets, standing seam roofs, and roof tiles. Galvanized steel coils are also used to make wall panels, structural components, beams, and columns.

The Automobile Industry

Galvanized steel coils are used in the automotive sector to make a variety of parts and components. Body panels, chassis components, frames, reinforcements, exhaust systems, and structural sections are examples of these. Galvanized steel's corrosion resistance helps to protect automobiles from rust and extends their lifespan.

Household Goods and Appliances

Appliances such as refrigerators, air conditioners, washing machines, and ovens are made from galvanized steel coils. They're also utilized to make kitchenware, tools, cabinets, and other household items.

HVAC Systems

Galvanized steel coils are extensively used in HVAC systems (heating, ventilation, and air conditioning). Because of their longevity and resistance to corrosion in high-moisture settings, they are used to manufacture air ducts, vents, and other components.

Agricultural Machinery

Galvanized steel coils are used in the agricultural industry to make equipment like grain silos, barns, fences, and agricultural machines. Galvanized steel's corrosion resistance improves the lifetime and dependability of these structures and equipment.

Telecommunications and Electricity

Electrical enclosures, cable trays, and support structures for electrical and telecommunication systems are made from galvanized steel coils. The zinc coating helps to preserve these components from corrosion.

Industrial Applications

Galvanized steel coils are widely employed in a wide range of industrial applications, including industrial roofing, storage tanks, pipes, and scaffolding. Galvanized steel is suitable for harsh industrial situations because of its corrosion resistance and strength.

Galvanized Steel Coil Types

Hot-Dip Galvanized Steel Coils

This is the most popular and commonly utilized form of galvanized steel coils. During the hot-dip galvanizing process, steel coils are immersed in a bath of molten zinc, establishing a metallurgical bond with the steel surface. The result is a thick and long-lasting zinc coating with exceptional corrosion resistance. Hot-dip galvanized steel coils are renowned for their rust-resistant properties and find widespread use across various industries.

Electro-Galvanized Steel Coils

In the electro-galvanizing process, a thin layer of zinc is applied to steel coils through electrolysis. Unlike hot-dip galvanizing, electro-galvanizing does not involve immersion in molten zinc. Electro-galvanized steel coils have a thinner zinc coating compared to hot-dip galvanized coils. They offer modest corrosion resistance and are often used in applications where a lighter coating is sufficient or where a smooth and consistent appearance is desired.

Manufacturing Process

Surface Preparation

The journey begins with the preparation of the steel substrate. Raw steel coils are subjected to a thorough cleaning process to remove any contaminants, such as rust, oil, or dirt, from the surface. This preparation ensures optimal adhesion of the zinc coating that will be applied in subsequent steps.

Galvanizing Bath

Once cleaned, the steel coils are immersed in a bath of molten zinc. This step, known as hot-dip galvanizing, is pivotal to the process. The zinc bath is maintained at a high temperature to ensure proper metallurgical bonding between the zinc and the steel. This metallurgical bond enhances the durability and longevity of the resulting galvanized steel.

Alloying and Solidification

As the steel coils are withdrawn from the galvanizing bath, excess molten zinc drips off, leaving behind a layer of zinc that adheres to the steel surface. During this phase, alloying may occur between the zinc and the steel, further enhancing the bond between the two materials. The zinc layer solidifies on the steel substrate, forming the protective coating.

Cooling and Inspection

The galvanized steel coils are then cooled, allowing the zinc coating to fully solidify and bond to the steel. After cooling, the coils undergo thorough inspection to ensure uniformity of the coating thickness and its adherence to the steel. This inspection is crucial to ensuring that the final product meets the required quality standards.

Post-Treatment (Optional)

Depending on the intended application and desired characteristics, galvanized steel coils may undergo additional treatments. One common post-treatment is passivation, which involves applying a chemical solution to the zinc coating to enhance its corrosion resistance. Additionally, a topcoat may be applied for aesthetic purposes or to provide additional protection against specific environmental factors.

Thickness of Zinc Coating

The thickness of zinc-coated galvanized steel coils is an important component in determining both quality and cost. In general, thicker coatings provide superior corrosion protection and longevity. The thickness of the zinc coating is defined in terms of coating weight, which is usually given in grams per square meter (g/m²) or ounces per square foot (oz/ft²). Because of the increased amount of zinc required, larger coating weights frequently result in higher cost.

Steel Grade and Composition

The quality and kind of steel used to make the coils are important factors in determining overall quality. Steel grades differ in terms of mechanical qualities such as strength, ductility, and formability. Prime galvanized steel coils with desirable mechanical characteristics are often more expensive.

Manufacturing Methodology

The process used to galvanize steel coils influences both quality and cost. Hot-dip galvanizing, which involves immersing the steel in a bath of molten zinc, produces a thicker and more lasting coating than electro-galvanizing, which uses electrolysis to apply a thinner layer of zinc. Hot-dip galvanized coils have stronger corrosion resistance and are sometimes more expensive than electro-galvanized coils.

Coating Uniformity and Adherence

The uniformity and adherence of the zinc coating to the steel surface determine its quality. A homogeneous and well-adhered coating provides consistent corrosion protection. Poor coating adhesion or imperfections can lead to lower quality and may have an impact on cost.

Steel Coil Specifications

Steel coil specifications, such as thickness, width, and length, might influence pricing. Thicker and broader coils necessitate more raw materials and processing, which raises the cost. Longer coils may also incur additional handling and transportation costs.

Galvanized Steel Coil Market

Market dynamics such as supply and demand influence galvanized steel coil prices. Pricing can be affected by fluctuations in raw material supply, changes in manufacturing capacity, and market competition. Furthermore, the cost of galvanized steel coils can be influenced by global trade dynamics and economic considerations.

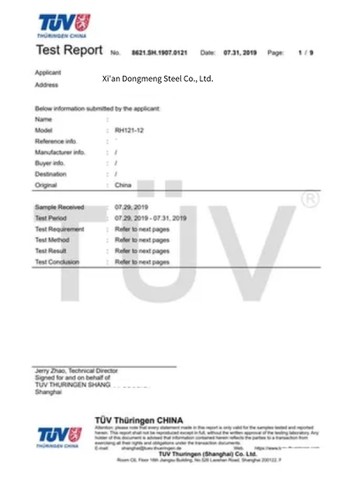

Certifications and Standards of Quality

Compliance with established quality certifications and standards, such as ISO, ASTM, or specialized industry requirements, can indicate the quality and dependability of galvanized steel coils. Due to the additional quality assurance measures involved, coils that fulfill demanding quality requirements and have applicable certifications may attract higher pricing.

Supplier Reputation and Brand

A supplier's or manufacturer's reputation and brand value can influence both galvanized steel coils price and perceived quality. Well-established and reputable suppliers frequently have a track record of producing high-quality items and may charge a premium for the value of their brand and client trust.

Our Factory

Companies We Have As Clients

Our Certifications

Ultimate Guide

Hot Tags: galvanized steel coil, China galvanized steel coil manufacturers, suppliers, factory

You Might Also Like