Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Galvanized Steel Wire

1) Application: Fencing wire (Panel wire), Bucket handle wire, Baling wire, Vineyard wire, Fine mesh wire, PVC coated wire, Spring Wire, Roping Wire, ACSR core wire, for Automatic rebar tying machine and other application. 2) Material: low carbon steel, middle carbon steel and high carbon steel 3) Diameter: 0.15mm~8.00mm 4) Tensile Strength: 300-500MPA, 400-600MPA, 700-1200MPA, min.1200MPA, min.1700MPA 5) Packing: 0.2kg~800kg, in small coils, big coils and on spool or drums 6) Standard: ASTM 641, BS EN10244 etc. 7) All can be produced according to customers’ actual requirement.

Description

Galvanized Wire

Galvanized steel wire is defined as a steel wire that has been coated with zinc to protect it from corrosion called galvanization.

The galvanization process involves applying a zinc layer to the steel wire's surface, creating a barrier that prevents oxygen and water from reaching the steel, which causes it to rust.

Galvanized steel wire is used in various applications, including construction, fencing, and agriculture.

It is also often used as an electrical conductor because it is less to corrode than other types of wire. Galvanized steel wire is an important material that helps prolong steel products' life and protect them from the elements.

Applications of Galvanized Wire

There are several different applications for galvanized wire, including

• Fencing and enclosures: Galvanized wire helps construct fence panels and gates. The zinc coating helps to protect the wire from rusting, making it an ideal material for outdoor use.

• Hanging support: Galvanized wire creates various hanging supports, such as clotheslines and curtain rods. The strong and durable nature of the wire makes it ideal for supporting heavy items.

• Securing windows: Galvanized wire can be used in different settings, such as homes, offices, and stores. The wire can be wrapped around the window frame and secured with nails or screws.

• Binding, Tying, and Baling: Galvanized wire rope and galvanized tie wire can be used for various binding, tying, and baling applications. The strong and durable nature of the wire makes it ideal for these purposes.

• Recycling: Galvanized wire can be recycled into new steel products. This recycling process helps to reduce environmental pollution and conserve natural resources.

• Packaging: Galvanized wire is often used in packaging applications because it holds objects securely.

Also, galvanized wire mesh is commonly used in construction and manufacturing as fencing, reinforcement, or protective barrier.

Benefits of Galvanized Wire

There are several benefits of high-tensile galvanized wire, including

• The high tensile strength of the wire makes it ideal for various applications, such as construction, fencing, agriculture, and industrial applications.

• These wires are corrosion-resistant compared to other materials.

• The wire is less likely to corrode than different types of wire, making it an ideal choice for electrical conductor applications.

• The galvanized wire comes in various gauges to suit your specific needs.

• The wire can be recycled into new steel products, helping to reduce environmental pollution and conserve natural resources.

Galvanized Wire Gauge Chart

Below is a wire gauge chart for your reference.

| Wire gauge size | SWG(mm) | BWG(mm) | Metric(mm) |

| 8 | 4.06 | 4.19 | 4.00 |

| 9 | 3.66 | 3.76 | – |

| 10 | 3.25 | 3.40 | 3.50 |

| 11 | 2.95 | 3.05 | 3.00 |

| 12 | 2.64 | 2.77 | 2.80 |

| 13 | 2.34 | 2.41 | 2.50 |

| 14 | 2.03 | 2.11 | – |

| 15 | 1.83 | 1.83 | 1.80 |

| 16 | 1.63 | 1.65 | 1.65 |

| 17 | 1.42 | 1.47 | 1.40 |

| 18 | 1.22 | 1.25 | 1.20 |

| 19 | 1.02 | 1.07 | 1.00 |

| 20 | 0.91 | 0.89 | 0.90 |

| 21 | 0.81 | 0.813 | 0.80 |

| 22 | 0.71 | 0.711 | 0.70 |

Hot Dipped Galvanized VS Electro Galvanized Wire

You can find two kinds of galvanized steel wire for sale, namely, hot-dip GI wire and electro-galvanized steel wire. At SZ DEPU METALS, we offer both steel wire with electro-galvanized and hot-dip galvanized coatings. Below let's review their differences.

1. Zinc layer thickness: The maximum zinc content can reach up to 300 g/m2 for the hot-dipped one; while that of cold galvanized one is only 3-15 g/m2.

2. Corrosion resistance. The hot dip galvanizing wire has better corrosion resistance than the electro galvanized one. Generally, its service life is more than 10 years even in outdoor environment. However, electro-galvanized is a physical process in which a layer of zinc is applied to the surface of the wire by electroplating. The thickness of the finished coating is smooth and shiny, but thin. Generally, it can only last a few months. So it is not as durable as the hot-dip galvanized one.

3. Difference appearance. Hot-dip galvanizing wire has a dull and unpleasant finish. While electro galvanized wire has a smooth surface and bright appearance.

4. Difference in price. Hot dip galvanizing is more expensive when compared to electro-galvanizing. But the zinc coating of the former is thicker and the longer the service life. So in the long term, the former one is more cost-effective.

5. Different applications. Because hot-dip galvanizing wire offers superior corrosion resistance, it can be used for any application including harsh or humid environments. For example, it is an ideal choice for oil processing, marine exploration, shipbuilding, gas transmission, scaffolding, bridge, road guardrail, and other agricultural and construction uses.

Hot-dip Galvanized Wire Price

The price of hot dip galvanizing wire is from USD 600 to USD 950 per ton. There are many factors that determine the price, especially the wire diameter and zinc coating thickness. Generally, the thicker the zinc coating, the higher the price. Except for the extreme thick or thin wire, the price differs little. As a base material, the lower the price, the higher the profits of finished products. But please do not rely on the price only to avoid being cheated. Besides, the price changes every day. SZ DEPU METALS, as a leading manufacturer and supplier of steel wire in China, will offer you a factory price. Welcome to contact us for the latest price now!

Hot-dip GI Wire Manufacturers

There are many hot dip galvanized wire manufacturers all over the world. Some are famous but offer a higher price. While some are not famous enough. They often offer a competitive price without compromising quality, for example, SZ DEPU METALS. We have our own factory. Our steel wires are made of high-quality carbon steel. Besides of wire production line, we also have galvanizing and PVC coated production lines. We can customize wire diameter, zinc coating thickness according to your needs. More than that, SZ DEPU METALS offers a full service system, which will reply you in 12 hours. If you have any questions, please contact us without hesitation.

Companies We Have As Clients

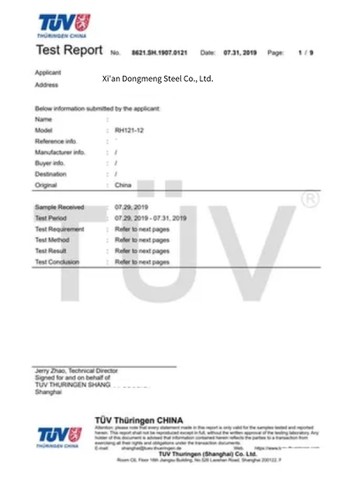

Our Certifications

Hot Tags: galvanized steel wire, China galvanized steel wire manufacturers, suppliers, factory

You Might Also Like