Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Galvanized Products

SZ DEPU METALS: Your Professional Galvanized Products Supplier

Shenzhen Depu Technology Co., Ltd. located in Xi'an High- tech Zone, Shaanxi, China, has been in business for over 30 years and is a professional manufacturer integrating R&D, production, sales and service. We are the leading provider of stainless steel sheets, coils, strips, tubes, bars, and custom stainless steel products and also specialized in the production and sales of galvanized wire, galvanized pipe, galvanized color-coated corrugated sheet and other products, which are widely used in construction, transportation, chemical industry and light industry.

Why Choose Us?

Extensive Inventory

With a vast stock holding of galvanized wire, galvanized pipe, aluminum products, stainless steel sheets, coils, strips, tubes, and bars, we have a wide range of products readily available to meet your immediate needs. Our comprehensive inventory ensures quick access to the materials you need.

High Quality

We only use the finest raw materials and have a rigorous quality control process in place. The products can meet the national standards, American standards, European standards and other foreign standards to meet the special technical needs of different customers. We've been awarded third-party certifications including ISO 9001-2015 and EN-1090-2. These absolutely verify our technical expertise and confirm that we meet the standards set by regulatory authorities.

Professional Team

We have more than 300 technical personnel, and the design engineers have more than 25 years of experience in designing and building molds that offer innovative solutions to complex design challenges. Our state-of-the-art equipment and skilled technicians offer laser cutting, plasma cutting, waterjet cutting and more, guaranteeing precise dimensions, clean finishes and no additional processing required.

Superior Service and Logistics

Our customer team is highly skilled, motivated and always ready. No matter you are following up on an order, looking for advice or seeking a bespoke quotation, our team is here to help. We partner with reliable logistics providers to offer secure and timely delivery. Our team handles all customs clearance, documentation, and transportation complexities to ensure your stainless steel arrives safely and efficiently.

Galvanized Steel Wire

Galvanized Steel Wire1) Application: Fencing wire (Panel wire), Bucket handle wire, Baling wire, Vineyard wire, Fine

Pre-painted Corrugated Metal Roofing Sheet

Pre-painted Corrugated Metal Roofing Sheet—Material :Pre-painted corrugated metal roofing sheet. —Grade:

Hot-Dip Galvanized Strip

Hot-Dip Galvanized StripThickness: 0.2-4.75mm. Width: 32-595-1500mm. Zinc coating: 40g/m2-275g/m2. Grade:DX51D /

Galvanized Sheet

Galvanized SheetSpecifications: Q215A, Q215B, Q235B, Q195, Q275Length: common length 5.8m, 6m, 11.8m, 12m or as

Galvanized Steel Coil

Galvanized Steel CoilThe zinc coating acts as a barrier between the steel and its surroundings, preventing rust and

Corrugated Galvanized Steel Roofing Sheet

Corrugated Galvanized Steel Roofing SheetProduct name: Corrugated Galvanized Steel Roofing SheetThickness: 0.12 mm to 1.2 mmWidth: 600 mm to

PPGI PPGL Prepainted Steel Coil

PPGI PPGL Prepainted Steel CoilThickness:0.12-1.2mmWidth:30-1250mmColor: Ral color codeInner diameter: 508/610mmCoating types: PE,

Galvanized Steel Coil

Galvanized Steel CoilThickness: 0.13-0.8 mm. Width: 600-1250 mm. Zinc coating: 30g/m2-275g/m2. Grade: Q195, Q235.

Galvanized Square Tube

Galvanized Square TubeSpecifications: Q215A, Q215B, Q235B, Q195, Q275Length: common length 5.8m, 6m, 11.8m, 12m or as

Galvanized products refer to metal products with a layer of zinc plated on the surface. Galvanized products have many advantages, such as strong anti-corrosion performance, long service life, and beautiful appearance. Therefore, they are widely used in construction, transportation, electricity, communications, home appliances and other fields. Our galvanized products include corrugated galvanized roofing sheet, PPGI prepainted steel coil, galvanized steel coil and galvanized square tube.

Advantages of Corrugated Galvanized Roofing Sheets

High Durability

A corrugated galvanized roof is made of zinc-coated steel sheet, which makes it corrosion resistant. Generally, its service life is more than 30 years under normal conditions.

High Strength

Corrugated galvanized roofing sheets keep the strength of steel. Also, the corrugated design will improve the strength. As a roofing sheet, it can withstand extreme weather, like heavy snow, wind, etc.

Easy Installation

Corrugated galvanized roofing sheet is light in weight, which makes it easy to transport and quick to install. Also, galvanized roofing sheets are with a smooth and shiny surface. So you can use them as roofing panels directly without decoration.

Eco-friendly & Affordable Solution

Compared to other roofing materials, the galvanized corrugated roof is more affordable. And it is recyclable, which is very suitable for temporary buildings.

How to Install Corrugated Galvanized Roofing Sheets?

Cutting Corrugated Galvanized Roofing Sheet

Most galvanized corrugated roofing sheets are about 10 meters long. If you need to lap the whole sheet, at least 50 cm of lap length should be reserved. Therefore, cut the galvanized corrugated roofing sheet according to the required size.

Drilling

If the holes are not drilled on the galvanized corrugated roofing sheet, you need to use a drill bit and drill holes in the crest of the corrugated sheet.

Install Corrugated Galvanized Roofing Sheet

Place the galvanized corrugated roofing sheet directly on the purlins of the roof trusses and install it from the outer edge position. Seal both ends with wood or plastic strips to prevent leakage of rain and wind. Put screws into the drilled holes, fasten the corrugated sheet with screws and install the other side of the roofing sheet in the same way.

Check the Overlapping

Corrugated galvanized roofs are similar in tiles in that they need to be snugly overlapped. The seams should be sealed and you need to check the joins between the sheets for dents and bends, to ensure there is no gap for moisture to get in.

Check Your Screws

The first step to ensuring a corrugated roof is installed correctly is to ensure that the right rustproof, self-drilling screws are being used. Make sure they are installed straight and seated correctly, with a large enough washer to prevent leaks. When you check your roof periodically, replace any broken or loose fasteners and install new ones, as they need to be tightly assembled and kept dry to endure for years.

Clean the Roof

One of the larger causes of damage and corrosion is leaving debris and dirt on the roof. Metal shavings, rivets and screws all have the potential to rust and spread that oxidation onto the roof surface itself.

Advantages of Using Galvanized Steel Coil

One of the main advantages of using galvanized steel coils is its exceptional durability. The galvanizing process involves coating steel with a layer of zinc, which provides excellent protection against corrosion and rust. This makes galvanized steel coil a durable material that can withstand harsh environmental conditions, including exposure to moisture and extreme temperatures. As a result, structures and equipment made from galvanized steel coils last longer and require less maintenance, saving time and money in the long run.

Zinc coating provides an extra layer of protection, making the steel more resistant to impact and wear. This makes galvanized steel coils ideal for applications requiring high levels of structural integrity and durability, such as the construction of buildings, bridges and industrial equipment. Additionally, the strength of galvanized steel coils allows for thinner, lighter structures, resulting in cost savings and increased efficiency.

Another advantage of galvanized steel coil is its versatility. It can be easily formed, welded and manufactured into a variety of shapes and sizes, making it suitable for a wide range of applications. Whether used for roofing, siding, fencing or fabrication, galvanized steel coils offer flexibility and adaptability to meet varying needs. The ability to tailor materials to specific requirements makes it an attractive option for architects, engineers and manufacturers.

Galvanized steel coils are environmentally friendly and sustainable. Zinc coating provides a barrier that protects the underlying steel from corrosion, extending its service life and reducing the need for frequent replacement. This reduces waste and lowers resource consumption, making it a more sustainable choice compared to other materials. Additionally, the recyclability of steel makes galvanized steel coil an environmentally friendly option, supporting green building practices and environmental protection efforts.

Galvanized steel coils are cost-effective. While the initial investment may be slightly higher than other materials, the long-term benefits and savings outweigh the upfront costs. Its durability, low maintenance requirements and longer service life help reduce overall costs over time. Additionally, the versatility and ease of handling of galvanized steel coils reduces labor and installation expenses, further increasing its cost-effectiveness.

Tips for Storing Galvanized Steel Coils

Indoor Storage: Whenever possible, store galvanized steel coils indoors to protect them from environmental elements. This prevents exposure to moisture, which can lead to rust and compromise the zinc coating.

Dry Environment: Maintain a dry storage environment to prevent condensation. Moisture can accelerate corrosion, adversely affecting the galvanized surface. Consider using dehumidifiers in storage areas.

Ventilation: Adequate ventilation is essential to prevent the accumulation of humidity. Well-ventilated storage spaces contribute to a stable environment and minimize the risk of corrosion.

Avoid Rough Handling: Handle galvanized steel coils with care to prevent scratching or damaging the zinc coating. Implement proper lifting equipment and techniques to avoid any impact during transportation.

Use Gloves: Wear protective gloves during handling to prevent oils, salts, or other contaminants from transferring onto the galvanized surface. Contaminants can compromise the effectiveness of the zinc coating.

Vertical Storage: When stacking coils, store them vertically to prevent excessive pressure on the lower coils. This minimizes the risk of deformation and maintains the integrity of the zinc layer.

Construction: Galvanized steel coils are widely used in the construction industry for manufacturing various structural components such as beams, studs, joists, roofing panels, and decking. The zinc coating protects the steel from corrosion, making it suitable for outdoor and harsh environments.

Automotive: Galvanized steel coils are used in automotive manufacturing for making body panels, chassis components, frames, and other structural parts. The corrosion resistance of galvanized steel helps prolong the lifespan of automotive parts, especially in regions with harsh weather conditions.

Appliances: Many household appliances, such as refrigerators, washing machines, and air conditioners, use galvanized steel coils for their cabinets, panels, and internal components. The corrosion resistance of galvanized steel ensures the longevity and reliability of these appliances, even in humid environments.

HVAC (Heating, Ventilation, and Air Conditioning): Galvanized steel coils are commonly used in HVAC systems for ductwork, vents, and other components. The corrosion resistance of galvanized steel helps maintain the efficiency and performance of HVAC systems over time.

Industrial Equipment: Galvanized steel coils find applications in various industrial equipment such as storage tanks, silos, conveyor systems, and agricultural machinery. The zinc coating provides protection against corrosion, ensuring the durability and reliability of these components in industrial settings.

Electrical Enclosures: Galvanized steel coils are used for manufacturing electrical enclosures, cabinets, and panels due to their strength and corrosion resistance. These enclosures protect electrical components from environmental factors and mechanical damage.

Fencing and Guardrails: Galvanized steel coils are often used in the construction of fences, guardrails, and barriers for highways, railways, and industrial facilities. The corrosion resistance of galvanized ensures the longevity and structural integrity of these safety barriers.

Household Products: Galvanized steel coils are used in the manufacturing of various household products such as shelves, cabinets, furniture, and garden tools. The corrosion resistance and strength of galvanized steel make it suitable for both indoor and outdoor applications.

What is the Process for Galvanizing Galvanized Steel Coils?

Surface Preparation

The steel coils are cleaned to remove any surface contaminants such as oil, grease, or dirt. This is typically done using a chemical cleaning process or by immersing the coils in a degreasing solution.

Pickling

The coils are then immersed in a pickling solution, usually an acidic bath such as hydrochloric acid or sulfuric acid. This removes any remaining oxides and mill scale from the surface of the steel, preparing it for the galvanizing process.

Fluxing

After pickling, the coils are rinsed to remove any residual pickling solution and then immersed in a flux solution. The flux helps to prevent oxidation of the steel surface before it is galvanized and promotes the adhesion of the zinc coating.

Galvanizing

The prepared steel coils are passed through a bath of molten zinc at temperatures typically around 450°C (850°F). The coils are carefully submerged in the zinc bath, ensuring that the entire surface is coated with a layer of molten zinc. This process is known as hot-dip galvanizing.

Quenching

Once the steel coils have been galvanized, they are removed from the zinc bath and allowed to cool in the open air or by quenching in water. This solidifies the zinc coating and ensures that it adheres firmly to the surface of the steel.

Finishing

After cooling, the galvanized GI coils may undergo further processing such as skin-pass rolling or tension leveling to improve surface finish and flatness. They may also be cut to size and coil-wound for shipment to customers.

The Benefits of Galvanized Square Tube for Outdoor Projects

Superior Corrosion Resistance

One of the primary advantages of galvanized square tubes is their exceptional corrosion resistance. The zinc coating on the steel creates a protective barrier that shields the underlying metal from exposure to moisture, chemicals, and other corrosive elements. This makes galvanized square tubes perfect for outdoor projects that are exposed to harsh weather conditions, such as rain, snow, and UV radiation. Unlike untreated steel, galvanized tubes are less prone to rusting, ensuring their longevity and reducing maintenance requirements.

Longevity and Durability

Galvanized square tubes are renowned for their longevity and durability. The zinc coating acts as a sacrificial layer that corrodes over time, protecting the steel core from damage. This self-healing property makes galvanized square tubes highly resistant to scratches, abrasions, and impact. As a result, they can withstand heavy loads and retain their structural integrity, making them suitable for a wide range of outdoor applications. Whether used for constructing fences, gates, handrails, or outdoor furniture, galvanized square tubes offer superior strength and longevity compared to other materials.

Cost-Effectiveness

Another significant benefit of galvanized square tubes is their cost-effectiveness. While the initial cost of galvanized square tubes may be slightly higher than untreated steel or alternative materials, their long-term savings outweigh the upfront investment. The extended lifespan and minimal maintenance requirements of galvanized square tubes translate into reduced replacement and repair costs. Additionally, their resistance to corrosion eliminates the need for regular painting or coating, saving both time and money in the long run.

Versatility in Design and Application

Galvanized square tubes offer tremendous versatility in design and application. They are available in various sizes, thicknesses, and lengths, allowing for customization to suit specific project requirements. The square shape of these tubes provides additional structural stability and aesthetic appeal, making them an excellent choice for both functional and decorative purposes. From constructing fences, gates, and pergolas to building outdoor furniture and play equipment, galvanized square tubes offer endless possibilities for creative design and construction.

Environmentally Friendly

In today's environmentally conscious world, using materials that are sustainable and eco-friendly is of paramount importance. Galvanized square tubes meet these criteria, making them an environmentally friendly choice. The process of galvanization involves minimal waste, and the zinc coating is recyclable. Moreover, the longevity and durability of galvanized square tubes significantly reduce the need for replacements, thus minimizing the environmental impact associated with material production and disposal.

Ease of Installation

Installing galvanized square tubes is relatively straightforward. Their standardized dimensions and consistent quality ensure compatibility and ease of integration with other building components. With the availability of pre-cut lengths and a wide range of connectors and accessories, galvanized square tubes offer convenience and flexibility during installation. This ease of use translates into time and labor savings, making them a practical solution for outdoor projects with tight timelines or budget constraints.

Material Properties

Galvanized square tubes are mainly made of ordinary carbon steel materials, and the outer surface is galvanized to improve its corrosion resistance. The galvanized layer can effectively prevent the square tube from being oxidized and corroded during use, greatly extending the service life of the square tube and making it more suitable for use in outdoor environments. Rectangular tubes can be made of different materials, such as ordinary carbon steel, stainless steel, etc. Rectangular tubes of different materials can be selected according to different use scenarios.

Structural Shape

The cross-sectional shape of the galvanized square tube is square, and the four corners are exactly equal. The cross-sectional shape of a rectangular tube is rectangular, usually with two equal long sides and two equal short sides. The cross-sectional shapes of square tubes and rectangular tubes make them structurally different and play different roles in specific application scenarios.

Application Scenarios

Because galvanized square tubes have good anti-corrosion properties, they are often used in outdoor drainage and roof ventilation ducts of buildings. Square tubes are also relatively small in size and suitable for piping systems in some small buildings. Due to its structural characteristics, rectangular tubes are often used in larger engineering projects such as building trusses and support structures. The specifications of the rectangular tube are larger and can meet the engineering needs.

Regular maintenance

Regularly inspect and maintain galvanized square tubes, and promptly repair or replace damaged parts to prevent further corrosion and damage.

Avoid mechanical damage

During transportation, installation and use, avoid mechanical damage to the galvanized square tube, such as scratches, collisions, etc., to maintain the integrity of the galvanized layer.

Prevent chemical corrosion

Avoid contacting galvanized square tubes with chemicals, such as acids, alkalis, etc., to prevent chemical corrosion from damaging the galvanized layer.

Avoid humid environments

Try to avoid exposing galvanized square tubes to humid environments for a long time, such as rain or soaking in water, to prevent corrosion and rust.

Regular cleaning

Clean the surface of galvanized square tube regularly to remove dust, dirt and other impurities, and keep it dry.

Use anti-corrosion coating

You can apply an anti-corrosion coating on the surface of galvanized square tube to increase its anti-corrosion ability.

Reasonable storage

When storing galvanized square tubes, avoid accumulation of moisture and moisture, keep them dry and ventilated, and avoid contact with moist and corrosive materials.

Use appropriate protective measures

According to the usage environment and conditions of galvanized square tubes, use appropriate protective measures, such as waterproof coatings, anti-corrosion packages, etc., to protect the galvanized layer.

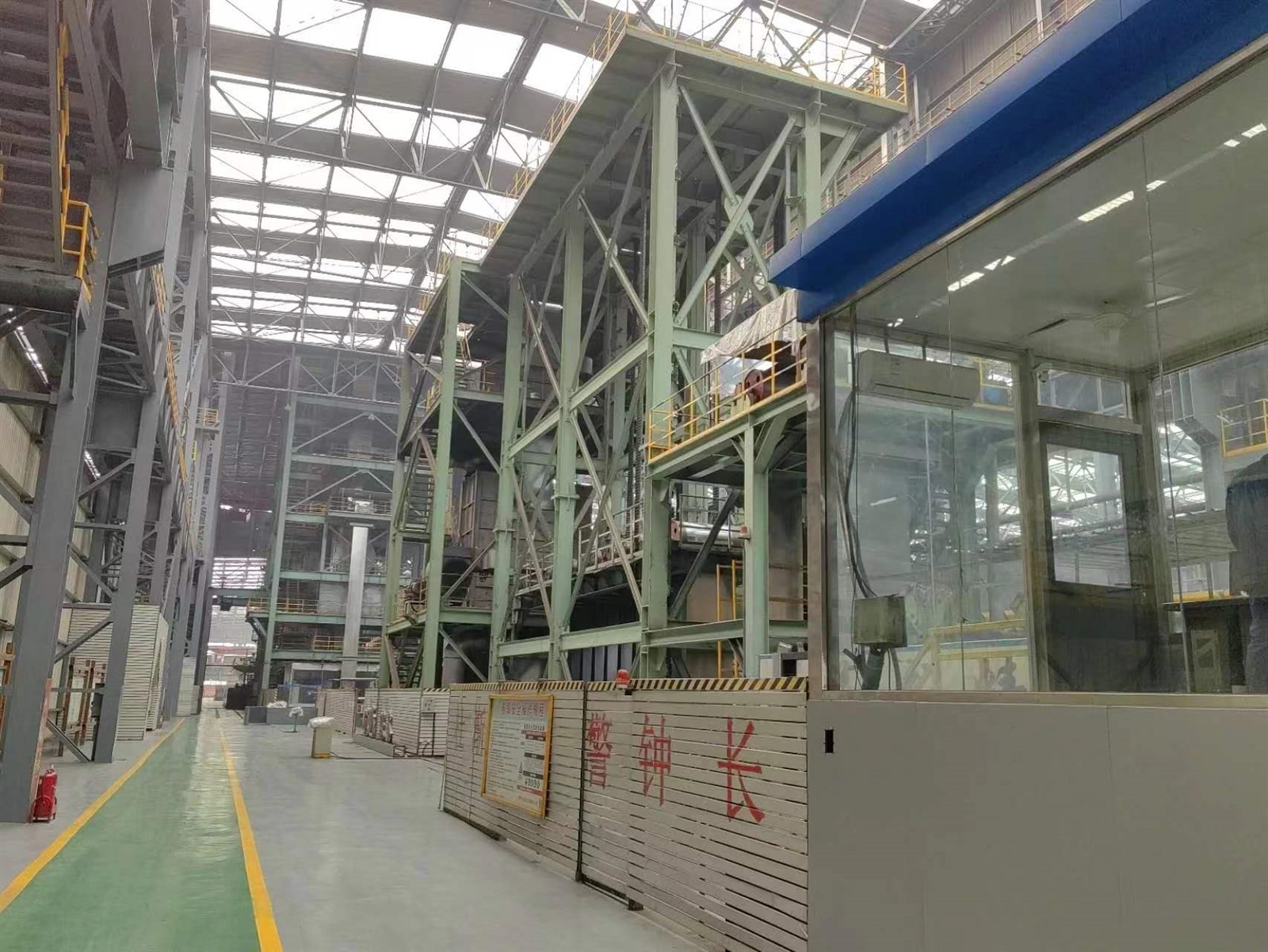

Our Factory

Companies We Have As Clients

Our Certifications

Ultimate Guide

As one of the leading galvanized products manufacturers and suppliers in China, we warmly welcome you to buy or wholesale cheap galvanized products in stock here from our factory. All customized products are with high quality and competitive price. For free sample, contact us now.