Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Water Ripple Stainless Steel Sheet

Why Choose Us Water Ripple Stainless Steel Sheet?

Water Ripple Stainless Steel Sheet is a unique material that is beautiful, durable and easy to clean, making it suitable for a variety of applications.

1. High quality materials:

We use high-quality 304 or 316 stainless steel plates, which have excellent corrosion resistance and durability.

We offer boards in a variety of thicknesses to meet your different needs.

We provide a variety of surface treatments, such as polishing, brushing, etching, etc., to meet your different aesthetic needs.

2. Rich products and customized services:

We offer panels in a variety of sizes to meet your different project needs.

We offer a customization service and can tailor special sizes, patterns, finishes and textures to your requirements.

3. Price and Service

We offer very competitive prices.

We provide prompt delivery and excellent customer service.

4. Professional and environmentally friendly

We have many years of experience and expertise in the production and sales of Water Ripple Stainless Steel Sheet

We have a dedicated team dedicated to providing you with quality products and services.

We are responsible for environmental protection and our production processes comply with environmental standards.

What Is A Water Ripple Stainless Steel Sheet

A water ripple stainless steel sheet is a type of metal sheet designed with a textured surface resembling the ripples that form on the surface of water. This texture is achieved through various methods, such as embossing or stamping, creating a visually appealing and unique aesthetic.

Water Wave Stainless Steel Panel

Water Wave Stainless Steel Panel—Material :water wave stainless steel panel . —Grade: 201/ 304 / 316L /430. —Thickness: 0.3mm –

Water Ripple Sheet Metal

Water Ripple Sheet Metal—Material :water ripple sheet metal . —Grade: 201/ 304 / 316L /430. —Thickness: 0.3mm – 2.0mm.

Ripple Stainless Steel Sheet

Ripple Stainless Steel Sheet—Material :ripple stainless steel sheet . —Grade: 201/ 304 / 316L /430. —Thickness: 0.3mm – 2.0mm.

Water Ripple Sheet For Ceiling

Water Ripple Sheet For Ceiling—Material : water ripple sheet for ceiling . —Grade: 201/ 304 / 316L /430. —Thickness: 0.3mm –

Benefits Of Water Ripple Stainless Steel Sheet

Aesthetic appeal:

The unique texture adds visual interest and elevates the design of any space.

Durability:

Stainless steel offers long-lasting performance and requires minimal maintenance.

Corrosion resistance:

Suitable for use in harsh environments with minimal risk of rust or damage.

Recyclable:

Stainless steel is an environmentally friendly material that can be recycled repeatedly.

Things to consider when choosing water ripple stainless steel sheets:

Thickness:

Choose a thickness that suits your application's needs, considering factors like structural requirements and desired effect.

Finish:

Select a finish that complements your overall design aesthetic and desired level of reflectivity.

Grade of stainless steel:

Different grades offer varying levels of corrosion resistance and mechanical properties. Choose based on your project's specific requirements.

Supplier:

Select a reputable supplier who offers high-quality materials and can provide necessary technical support.

Types Of Water Ripple Stainless Steel Sheet

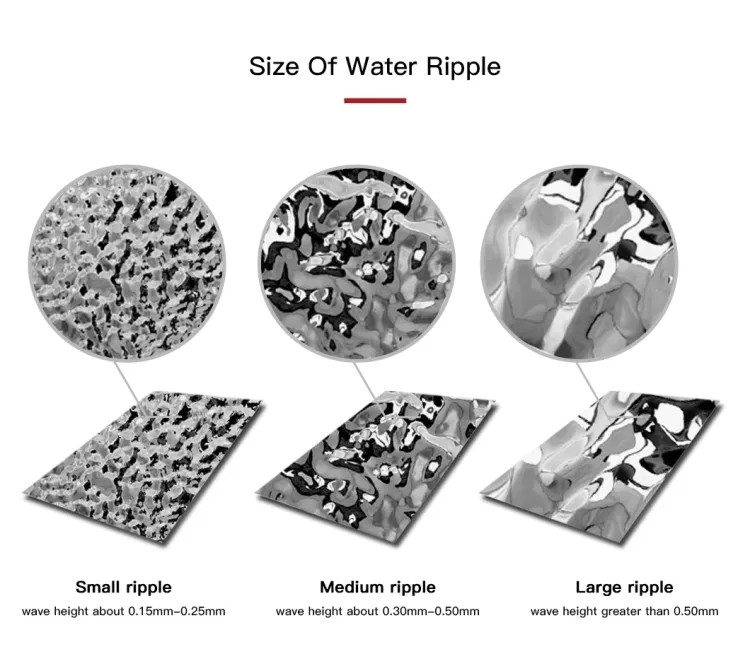

By Size of Ripples:

- Small Ripple: These sheets have a wave height of about 0.15mm to 0.25mm, creating a subtle and elegant texture. They are often used for indoor applications such as wall panels, furniture elements, and decorative accents.

- Medium Ripple: With a wave height of 0.30mm to 0.50mm, these sheets offer a more pronounced texture, adding visual interest and depth to a surface. They are suitable for both indoor and outdoor applications, such as building facades, elevator cladding, and signage.

- Large Ripple: Featuring a wave height exceeding 0.50mm, these sheets make a bold statement with their dramatic texture. They are often used for outdoor applications where a strong visual impact is desired, such as architectural cladding, sculptures, and fountains.

By Material:

- 304 Stainless Steel: This is the most common type of water ripple stainless steel sheet due to its affordability, good corrosion resistance, and ease of fabrication. It is suitable for most indoor and outdoor applications

- 316 Stainless Steel: Offering superior corrosion resistance compared to 304, this type is ideal for applications exposed to harsh environments such as marine settings or areas with high humidity.

- Colored Stainless Steel: By adding a PVD coating, manufacturers can create water ripple sheets in various colors like gold, rose gold, black, and blue. These sheets add a touch of luxury and sophistication to any project

By Finish:

- Polished: This finish provides a reflective and mirror-like surface, highlighting the water ripple pattern and creating a glamorous looket

- Brushed: This finish creates a matte and satin-like surface, softening the water ripple pattern and offering a more contemporary aesthetic

- Etched: This process deepens the water ripple pattern for a more pronounced and three-dimensional effect. It is often used for artistic applications or to create a unique visual texture.

Key characteristics of water ripple stainless steel sheets:

Distinctive texture:

The textured surface mimics water ripples, adding visual interest and dimension to any project.

Durable and weather-resistant:

Stainless steel offers excellent durability and resistance to corrosion, making it suitable for both indoor and outdoor applications.

Reflective properties:

The smooth surface reflects light, adding a touch of shine and enhancing the visual appeal.

Variety of finishes:

Available in various finishes like polished, brushed, or mirror-polished, catering to different design preferences.

Versatility:

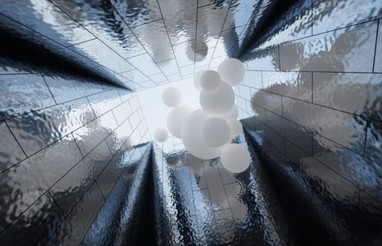

Can be used in various applications, including architectural projects, wall panels, ceilings, facades, elevator cabins, car box panels, signs, water features, and more.

Application of Water Ripple Stainless Steel Sheet

Craftsmanship Water Ripple Stainless Steel Sheet

Material Selection:

Grade: High-quality grades like 316L stainless steel offer superior corrosion resistance and durability, ideal for outdoor applications or demanding environments.

Thickness: Choosing the appropriate thickness ensures structural integrity and maintains the desired aesthetic. Thicker sheets offer a bolder texture and greater strength, while thinner sheets provide flexibility and a more subtle effect.

Pattern Design and Creation:

Authenticity: Craftsmanship often involves replicating natural water ripples, ensuring a nuanced and organic texture unlike mechanically produced patterns.

Depth and Dimension: Handcrafted techniques like etching or embossing can create deeper, more defined ripples with subtle variations, adding a sense of realism and depth.

Finishing Techniques:

Polishing: Skilled polishing techniques create a smooth, reflective surface that accentuates the water ripple pattern and enhances the overall shine and elegance.

Brushing: Hand-brushing techniques achieve a uniform satin finish with subtle directional lines, adding a touch of warmth and texture.

Etching: Artisanal etching methods can create a more pronounced and three-dimensional effect, highlighting the ripple details and adding a unique artistic element.

Custom Fabrication:

Tailor-made solutions: Skilled craftspeople can create bespoke sheets with specific sizes, patterns, and finishes to perfectly match your project requirements.

Seamless integration: Precision fabrication ensures accurate cuts, bends, and welds, resulting in flawless integration and a professional finish.

Additional factors:

Experience and expertise: Craftsmanship relies on the knowledge and skill of experienced artisans who understand the nuances of working with stainless steel and water ripple patterns.

Quality control: Meticulous attention to detail during every stage of production, from material selection to final finishing, ensures a flawless and high-quality end product.

How to Maintain Water Ripple Stainless Steel Sheet

Here are some tips on how to maintain your water ripple stainless steel sheet:

General Cleaning:

Regular cleaning: Wipe down the sheet regularly with a mild detergent solution and a soft cloth. Rinse thoroughly with clean water and dry completely with a microfiber cloth to avoid water spots.

Avoid harsh chemicals: Do not use harsh chemicals, abrasives, or scouring pads on the sheet, as they can damage the surface and dull the finish.

Remove stains promptly: Clean up spills and stains immediately to prevent them from setting in. For tougher stains, use a specialized stainless steel cleaner or a paste made of baking soda and water.

Additional Tips:

Polished finishes: Polished finishes require more frequent cleaning to maintain their shine. You can use a commercial stainless steel polish to enhance the shine if needed.

Brushed finishes: Brushed finishes are more resistant to fingerprints and scratches but can still accumulate dust and grime. Use a soft brush to remove dust and a mild detergent solution for cleaning.

Outdoor sheets: For outdoor sheets exposed to elements, regular cleaning is crucial to prevent dirt buildup and potential discoloration. Consider using a pressure washer with a mild soap solution and rinsing thoroughly.

Salt environments: If your sheet is exposed to salt environments, rinse it frequently with fresh water to prevent corrosion.

Prevent scratches: Avoid dragging objects across the sheet as it can scratch the surface. Use felt pads under furniture or other objects that might come in contact with the sheet.

10.effect steps Water Ripple Stainless Steel Sheet

The effect of a water ripple stainless steel sheet primarily comes from the texture and finish, which mimic the appearance of water ripples. There are several steps involved in creating this effect:

1. Material Selection:

High-quality stainless steel (e.g., 304 or 316) is chosen for its durability and aesthetic appeal. Thicker sheets may be used for a bolder texture, while thinner options offer flexibility and a subtler effect.

2. Pattern Creation:

Two main approaches exist:

Mechanical methods: Rolling mills with patterned rollers or laser etching can create consistent, uniform ripples.

Handcrafted methods: Artisans might use techniques like embossing, hammering, or etching to create more organic and nuanced ripple patterns with depth and variation.

3. Finishing:

Different finishes enhance the appearance and texture:

Polishing: Creates a reflective surface, emphasizing the ripples and providing a glamorous look.

Brushing: Offers a matte, satin finish, softening the ripples for a contemporary aesthetic.

Etching: Deepens the ripples for a pronounced, three-dimensional effect, often used for artistic applications.

4. Additional factors:

Color: Some sheets are coated with PVD technology to achieve various colors like gold, rose gold, black, or blue, adding a unique design element.

Customization: Skilled artisans can create bespoke sheets with specific sizes, patterns, and finishes to match specific project requirements.

Frequently Asked Questions Water Ripple Stainless Steel Sheet

As one of the leading water ripple stainless steel sheet manufacturers and suppliers in China, we warmly welcome you to buy or wholesale cheap water ripple stainless steel sheet in stock here from our factory. All customized products are with high quality and competitive price. For free sample, contact us now.