Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

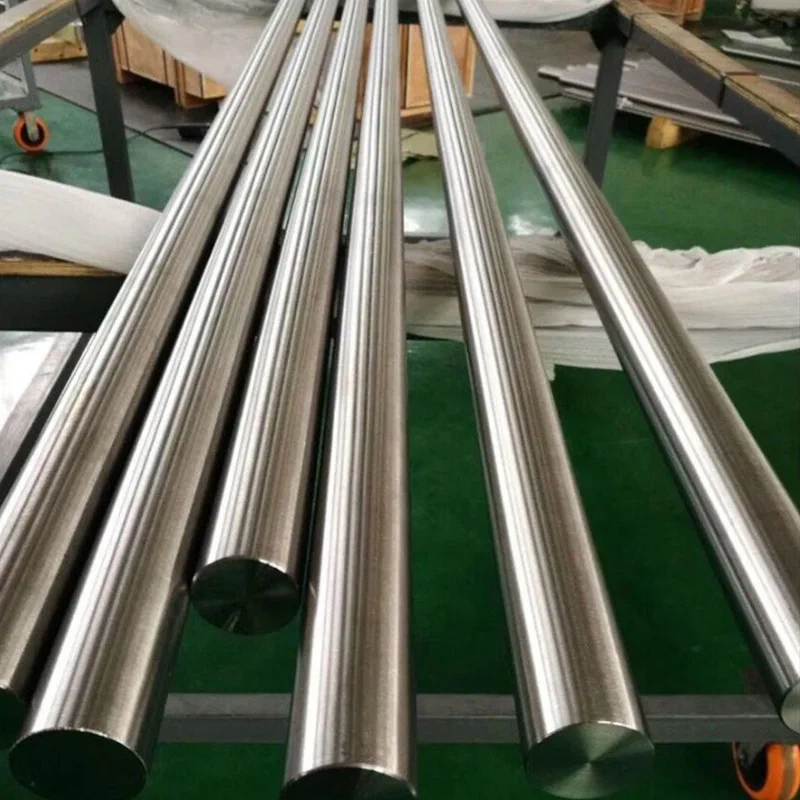

Titanium Alloy Wire And Bar

Wire: 0.03937 – 0.3937 in. (1.0 – 10mm)

Bar: 0.3937 - 12.00 in (10 - 300mm)

MOQ: 50Kg

Email:info@szdepu-metals.com

Description

who choose us?

Titanium alloy wire and bar can be formed and machined using a variety of techniques. Common forming methods include bending, drawing, and swaging. Machining of titanium alloys can be more challenging than machining steel due to its high strength and low thermal conductivity. However, with proper tooling and techniques, titanium alloys can be machined to produce complex shapes and components.

one-stop solution

professional team

high quality

competitive advantage

competitive price

long warranty

24H Online Service

Global Shipping

our casey

Excellent corrosion resistance:

Titanium alloys are highly resistant to corrosion, even in harsh environments such as seawater and chloride solutions. This makes them suitable for marine applications, chemical processing equipment, and oil and gas production.

Biocompatibility:

Certain titanium alloys are biocompatible, meaning they are well-tolerated by the human body and can be used in medical implants such as artificial joints, bone screws, and dental implants.

High heat resistance:

Titanium alloys maintain their strength at elevated temperatures, making them valuable for applications in high-temperature environments such as jet engines and power plants.

High strength-to-weight ratio:

Titanium alloys are significantly lighter than steel but can offer comparable or even superior strength. This makes them ideal for applications where weight reduction is a critical factor, such as in aerospace, automotive, and medical industries.

our services

large ecterprise scale

Wide Application Of Technology

standardized production

High-Quality Customized Services

order management

Responsibility

Xi'an SZ DEPU METALS

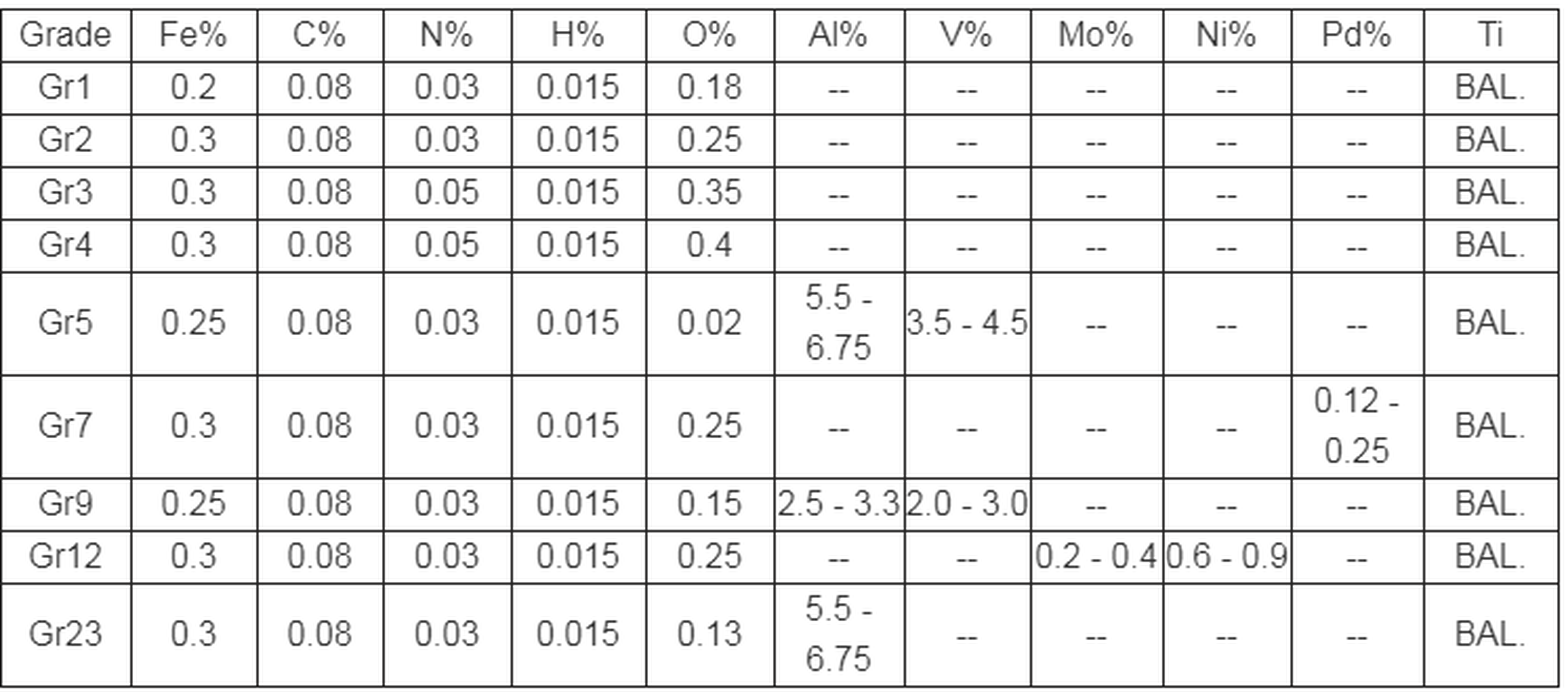

Titanium alloy wire and bar are available in a variety of grades, each with its own unique combination of properties. Some of the most common titanium alloy grades include:

Ti-6Al-4V:

This is the most widely used titanium alloy, offering a good balance of strength, ductility, and corrosion resistance.

Ti-6Al-4V ELI (Extra Low Interstitials):

This is a high-purity version of Ti-6Al-4V, used in medical applications where biocompatibility is critical.

CP Ti (Commercially Pure Titanium):

This grade of titanium offers excellent corrosion resistance and formability but has lower strength than titanium alloys.

Applications for titanium rods

Aerospace:Titanium rods are used in aircraft components such as fuselages, wings and engine components.

Automotive: Titanium rods are used in automotive components such as suspension components, braking systems, and exhaust systems.

Medical: Titanium rods are used in medical implants such as artificial joints, bone screws, and dental implants.

Chemical Processing: Titanium rods are used in chemical processing equipment such as reactors, pipes and valves.

Oil and Gas: Titanium rods are used in oil and gas production equipment such as drilling pipes, downhole tools and heat exchangers

We are committed to providing our customers with an exceptional buying experience. Our knowledgeable and friendly sales team is always available to assist you in selecting the right product for your needs. We offer prompt shipping and secure payment options to ensure a smooth and hassle-free purchase.

Our address

Xinwu District, Wuxi City, Jiangsu Province

Phone Number

+86 134 24179016

info@szdepu-metals.com

Hot Tags: titanium alloy wire and bar, China titanium alloy wire and bar manufacturers, suppliers, factory

You Might Also Like