Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Mirror Stainless Steel Plate

—Material : Mirror Stainless Steel Plate

—Grade: 201/ 304 / 316L /430

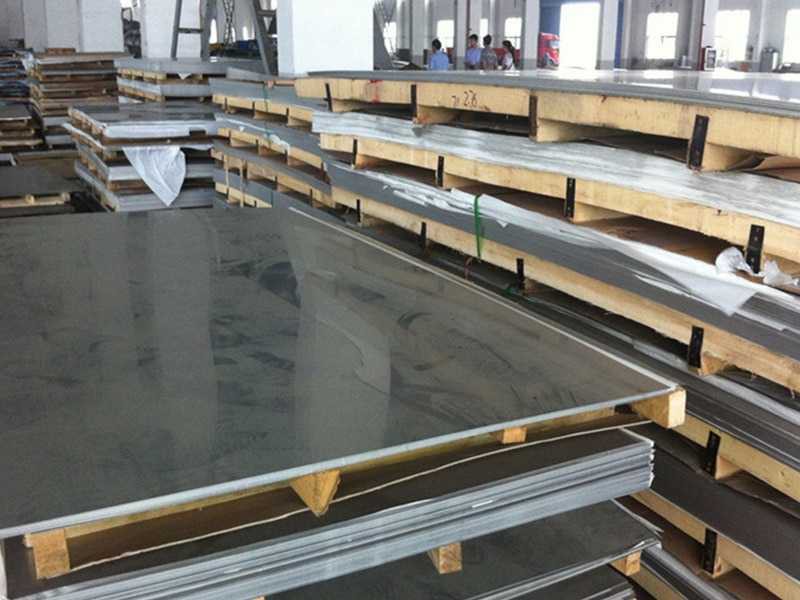

—Thickness: 0.3mm – 2.0mm

—Size: 1000mmx2000mm(39″x78″)/1219 x 2438 mm(48″ x96″) /1219 x3048mm(48″ x 120″)

Customized Size: available at requirement

ISO 9001:2015 certified

Description

Mirror Stainless Steel Plate

Mirror ss plate, This process involves multiple stages of grinding, buffing, and polishing with progressively finer abrasive materials to create a smooth and flawless finish.

It's important to handle mirrorss plate with care to prevent scratching or damaging the reflective surface. Regular cleaning using non-abrasive cleaners and soft cloths will help maintain their mirror finish.

| Steel Grade | |

| Thickness | 0.3mm-2mm |

| Standard size | 1000*2000mm/ 1219mm*2438mm/ 1220mm*2440mm /1500mm*3000mm |

| Surface finish | Mirror, 8K mirror, Super mirror |

| Origin of base sheet | Posco/ Tisco/ Jisco/ Bao steel/ HW |

| Color | Silver, metal color |

| Protective film | PE/PVC film |

| Lead time | Normally within 5 to 7 days |

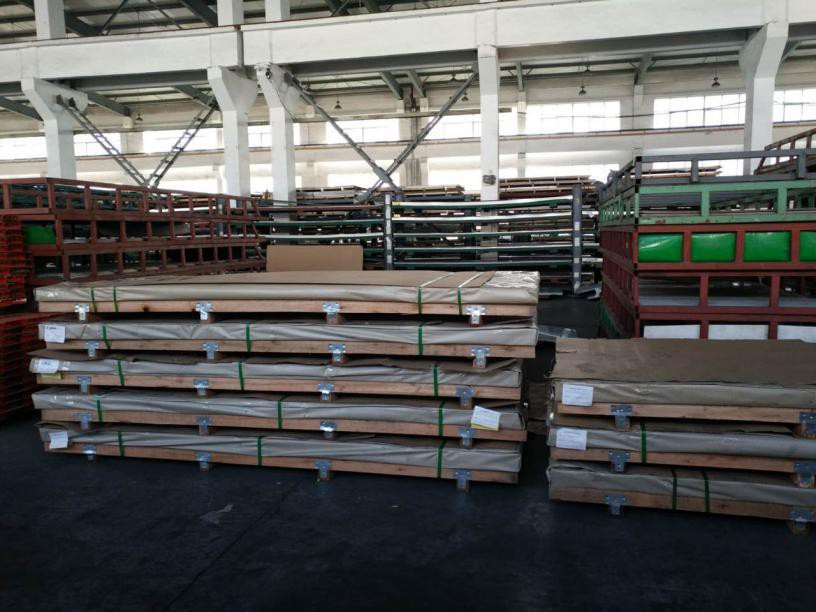

| Packing | Standard packing for sea freight or air freight |

| Payment terms | T/T or L/C |

| Application | Decoration, cabinets,etc |

| Welding request | Tig welding |

| Notice | Do not expose the film laminated sheet under the sun |

Can stainless steel be polished to a mirror finish?

Yes, it can be polished to achieve a mirror finish. The mirror finish, also known as a polished or reflective finish, is a highly smooth and reflective surface that resembles a mirror. It is a popular material for achieving this finish due to its inherent corrosion resistance and durability.

To achieve a mirror finish on that, a multi-step polishing process is typically employed. Here are the general steps involved:

Preparation: Start by cleaning the stainless steel surface to remove any dirt, oils, or contaminants. This can be done using a mild detergent or solvent and a clean cloth.

Grinding: Use a coarse abrasive material, such as sandpaper or a grinding wheel, to remove any surface imperfections, scratches, or blemishes. This step helps to create a smooth and even surface.

Buffing: Progress to successively finer abrasives, such as polishing compounds or diamond paste, along with a soft cloth or polishing wheel. Apply the abrasive material and gently move it in a circular motion across the stainless steel surface. This process helps to further refine the surface and enhance its reflectivity.

Final Polishing: Continue polishing with finer abrasives until the desired mirror finish is achieved. The final polishing steps may involve using a polishing compound specifically designed for stainless steel to bring out the highest level of shine.

Throughout the polishing process, it's important to maintain a consistent motion and pressure to ensure an even finish. It may be necessary to repeat certain steps or use different abrasives depending on the condition of the stainless steel and the desired outcome.

Applications

Exhibition and Trade Show Booths

Mirror stainless steel plates are often incorporated into exhibition and trade show booth designs. They create eye-catching displays, reflect lighting effects, and give a polished and professional look to the booth space.

Aerospace and Aviation

Mirror stainless steel plates find applications in the aerospace and aviation industries. They are used for decorative accents, cabin interiors, and aircraft fixtures, offering both aesthetic appeal and durability in demanding environments.

Outdoor Art and Installations

Mirror stainless steel plates can be utilized in outdoor art installations, sculptures, and architectural features. The mirror finish creates intriguing reflections and plays with the surrounding environment, adding an interactive and visually captivating element.

Luxury Packaging

Mirror stainless steel plates can be utilized in luxury packaging designs, such as for high-end cosmetics, perfumes, or premium products. The mirror finish adds a sense of luxury and sophistication to the packaging, enhancing the overall brand image.

Packaging

Get A Quick Quote

FAQ

Q: Are mirr ss plates scratch-resistant?

Q: What thicknesses are available for this product?

Q: Can this product be customized?

A: Yes, mirror ss plates can be customized to meet specific project requirements. This includes customization in terms of size, shape, and additional fabrication processes like laser cutting or etching. Working with a reputable supplier or fabricator will help in achieving the desired customization.

Q: Can mirror ss plates be used in high-temperature applications?

Hot Tags: mirror stainless steel plate, China mirror stainless steel plate manufacturers, suppliers, factory

You Might Also Like