Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

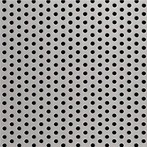

Drilling Stainless Steel Sheet

Drilling through this kind of sheets requires specific tools and techniques to ensure a clean and precise

cut without damaging the material. High-speed drill bits, drill presses, lubricants, and safety gear are

essential tools for drilling through stainless steel sheets. Common challenges include overheating, drill

bit breakage, and inaccurate holes, but these can be avoided by using the correct tools and techniques.

The market for drilling tools and techniques for stainless steel sheets is growing, with trends towards

the use of advanced materials, automation and robotics, customization, and sustainability.

Description

Stainless steel is a widely used material in many industries due to its excellent properties such as high resistance to corrosion and rust, strength, and durability. However, working with stainless steel can be challenging, particularly when drilling holes in stainless steel sheets. Drilling through a stainless steel sheet requires specific tools and techniques to ensure a clean and precise cut without damaging the material. In this article, we will discuss the process of drilling it in detail, including the tools and techniques used, common challenges, and market trends.

Part 1: Tools and Techniques used for drilling stainless steel sheets

Drilling through stainless steel sheets requires specific tools and techniques to ensure a clean and precise cut. The following tools are commonly used in the drilling process:

-

Drill bits - Stainless steel sheets are extremely hard, and therefore, require a high-speed drill bit to penetrate through the material. High-speed steel (HSS) or cobalt drill bits are typically used for this purpose. These drill bits have a sharp edge and can withstand the high temperature generated during the drilling process.

-

Drill press - A drill press is a machine used to drill precise holes in materials such as metal, wood, and plastic. When drilling through stainless steel sheets, a drill press is required to provide the necessary power and stability required for a clean and precise cut.

-

Lubricant - A lubricant is used during the drilling process to reduce friction and heat generated by the drill bit. This helps to extend the life of the drill bit and prevent damage to the stainless steel sheet.

-

Safety gear - When drilling through stainless steel sheets, it is important to wear safety gear such as gloves, goggles, and earplugs to protect yourself from potential hazards.

The following are the steps involved in drilling a hole through a stainless steel sheet:

►Step 1: Mark the spot where you want to drill the hole using a marker or center punch.

►Step 2: Attach the correct drill bit to the drill press.

►Step 3: Apply lubricant to the drill bit and the area where you will be drilling the hole.

►Step 4: Place the stainless steel sheet on the drill press and clamp it securely.

►Step 5: Start the drill press and slowly apply pressure to the drill bit.

►Step 6: Once the hole has been drilled, clean the area using a deburring tool to remove any rough edges.

Part2: Common challenges when drilling stainless steel sheets

Drilling through stainless steel sheets can be challenging due to the hardness of the material. The following are some common challenges you may face when drilling stainless steel sheets:

-

Overheating - Stainless steel sheets generate a lot of heat during the drilling process, which can cause the drill bit to become dull and the material to warp or discolor. To avoid this, it is important to use a lubricant to reduce heat and friction during the drilling process.

-

Drill bit breakage - The high hardness of stainless steel can cause the drill bit to break or snap if not handled correctly. It is important to use the correct type of drill bit and apply the correct amount of pressure when drilling through stainless steel sheets.

-

Inaccurate holes - If the stainless steel sheet is not clamped securely to the drill press or if the drill bit is not centered correctly, the resulting hole may be inaccurate or misaligned. To avoid this, it is important to clamp the sheet securely and ensure the drill bit is centered correctly before starting the drilling process.

Part3: Market trends

The demand for stainless steel sheets has been on the rise in recent years due to their excellent properties such as high resistance to corrosion and rust, strength, and durability. As a result, the market for drilling tools and techniques for stainless steel sheets has also seen significant growth. The following are some market trends in the drilling of stainless steel sheets:

Use of advanced materials - Manufacturers of drilling tools and equipment are increasingly using advanced materials such as diamond and tungsten carbide to produce high-performance drill bits that can withstand the high hardness of stainless steel sheets. These materials have improved durability and performance compared to traditional materials such as high-speed steel and cobalt.

Automation and robotics - Automation and robotics are becoming more prevalent in the drilling of stainless steel sheets. Automated drilling machines and robotic arms are being used in manufacturing industries to increase efficiency and precision in the drilling process.

Customization - Customized drilling solutions are becoming more popular in the drilling of stainless steel sheets. Manufacturers are offering customized drill bits and equipment to meet the specific needs of their customers, such as drilling different hole sizes and shapes.

Sustainability - The focus on sustainability in manufacturing industries has led to the development of more eco-friendly lubricants and cutting fluids for use in the drilling of stainless steel sheets. These products are biodegradable and do not contain harmful chemicals, making them a more sustainable choice for manufacturers.

Hot Tags: drilling stainless steel sheet, China drilling stainless steel sheet manufacturers, suppliers, factory

You Might Also Like