Contact Us

- Xinwu District, Wuxi City, Jiangsu Province

- info@szdepu-metals.com

- +86 134 24179016

Stainless Steel Round Tube

Stainless steel round tube offers a durable mill finish that can offer the right fit. Stainless steel round tubing typically comes either welded or seamless. 304 is the grade most often used and offers good machinability, corrosion resistance in many environments, and the ability to be sterilized.

Description

What is Stainless Steel Round Tube

Stainless steel round tube offers a durable mill finish that can offer the right fit. Stainless steel round tubing typically comes either welded or seamless. 304 is the grade most often used and offers good machinability, corrosion resistance in many environments, and the ability to be sterilized.

Why Choose Us

One stop solution

Our customer team is highly skilled, motivated and always ready. No matter if you are following up on an order, looking for advice or looking for a bespoke quotation, our team is here to help.

Custom service

With our manufacturing and design capability, it allows us to not only offer standard products, but also products based on customers' own specific designs.

High quality

As evidence of this quality, we've been awarded third-party accreditations including ISO 9001-2015 and EN-1090-2. These independently verify our technical expertise and confirm that we meet standards set by respected regulatory bodies.

Design

Our design engineers have more than 25 years of experience designing and building molds that offer innovative solutions to complex design challenges.

What is Stainless Steel Round Tube used for?

Stainless steel round tubes are utilized in a wide array of engineering and manufacturing applications due to their corrosion resistance, strength, and versatility. Their uses include:

Structural Applications

In construction and civil engineering, stainless steel tubes are used for support structures, handrails, balustrades, and fencing. They are chosen for their durability and ability to withstand harsh environmental conditions without rusting.

Mechanical Engineering

In mechanical systems, stainless steel tubes are employed for hydraulic and pneumatic lines, as well as for transporting gases and liquids under high pressure. The material's strength and resistance to corrosion make it ideal for these applications.

Automotive Industry

Stainless steel tubes are used in the automotive sector for exhaust systems, fuel lines, brake systems, and various fluid transfer applications. Their high-temperature tolerance and corrosion resistance are particularly beneficial in these environments.

Chemical Processing

Because of their resistance to chemicals and corrosive substances, stainless steel tubes are used in process piping and equipment within chemical plants, pharmaceutical facilities, and food and beverage processing industries.

Marine Applications

The saltwater environment is highly corrosive, so stainless steel tubes are commonly used in shipbuilding and marine engineering for hull reinforcement, propeller shafts, and various piping systems.

Medical Devices

Stainless steel tubes are used in medical equipment and devices, such as surgical instruments, catheters, and prosthetics, because of their biocompatibility and cleanliness.

Furniture and Design

In furniture design and architectural elements, stainless steel tubes are appreciated for their modern aesthetic and structural integrity. They are used for tables, chairs, and decorative features.

Heat Exchangers

Stainless steel tubes are used in heat exchangers due to their excellent thermal conductivity and corrosion resistance. They are essential in cooling systems, refrigeration, and HVAC applications.

Energy Sector

In renewable energy systems like wind turbines, stainless steel tubes are used for their strength and resistance to weathering. They are also employed in solar panel support structures and geothermal systems.

What are the Advantages of Stainless Steel Round Tube?

Introduction of Stainless Steel Round Tube

Stainless Steel Round Tube is a kind of hollow long round steel, which is widely used in industrial pipelines and mechanical structural parts such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrument and so on. Stainless Steel Round Tube is an economical type of steel. It is an important product of the iron and steel industry. Usually accounts for about 8%-16% of the total steel. It has a wide range of applications in the national economy. It is an economical profile of economical metal steel and an important part of high-efficiency steel, especially suitable for oil drilling, smelting and transportation industries.

Geological drilling, chemical industry, construction industry, machinery industry, aircraft and automobile manufacturing, boiler, medical equipment, furniture and bicycle manufacturing also require a large number of various Stainless Steel Round Tubes. Due to its hollow section, Stainless Steel Round Tubes are suitable for pipelines that transport liquids, gases and solids. At the same time, compared with the round steel of the same weight, the steel pipe has a larger section coefficient and higher resistance to bending and torsion, so it has become a variety of mechanical structures and building structures. Significant material on structures and components made of stainless steel tubing has a greater section modulus than solid components.

What are the advantages of Stainless Steel Round Tubes?

The Stainless Steel Round Tube has excellent mechanical properties, super wear resistance, and a thin and dense chromium-rich oxide film on the surface, which makes the Stainless Steel Round Tube have good water resistance in water including soft water, even if it is buried underground. Corrosive substances are underground. It also has excellent corrosion resistance. Rusty steel pipes can withstand high-velocity water erosion up to 30 m/s. The diversion Stainless Steel Round Tubes used in high-head power stations still have a service life of more than 100 years at the end of the nozzle with a water flow rate of more than 60m/s.

The tensile strength of Stainless Steel Round Tube is greater than 530N/mm, which is 2 times that of galvanized pipe, 3-4 times that of copper pipe, and 8-10 times that of PPR pipe. It has good ductility and toughness, which is conducive to saving water. Resource, beautiful, clean and fashionable appearance, 100% recyclable, good safety and hygiene performance, good temperature resistance, good thermal insulation performance, smooth inner wall, low water resistance, can work safely for a long time at -270℃-400℃, high temperature or No harmful substances will be precipitated at low temperature, and the material performance is quite stable.

The thermal insulation performance of Stainless Steel Round Tube is 24 times that of copper pipe, which reduces heat loss, is suitable for hot water transportation, does not cause environmental pollution, is green and environmentally friendly, and is conducive to sustainable development. Stainless steel scrap also has great economic value. Safe, non-toxic, non-corrosive, non-exuding, odorless, non-turbid, and no secondary pollution to water quality.

Stainless Steel Tubing for Many Applications

While there are many classic uses for stainless steel tube in the country's largest industries, there are many applications that you might never think of. Today we're going to demonstrate the versatility of the high-quality stainless steel tubing we produce, by exploring the depth of the industries and applications where stainless steel tubing plays an important role.

Tubing in every size

One of the reasons why stainless steel tubing is used in so many different ways is because it can be custom-manufactured in an extensive range of sizes and configurations. While some manufacturers specialize in a certain size, others like Atlantic Stainless have the facilities and technology to fabricate it in tiny sizes for use as hypodermic tubing, all the way up to very large sizes for use as pipes and industrial tubes. It's incredible to imagine that the same product can serve so many potential purposes when its size is changed! The measurements that come into play when choosing the ideal size of tubing for any given application are wall thickness, inner diameter, and outer diameter. Once those are chosen then the tube can be welded and drawn or cut and formed in any length!

The versatility of stainless steel tubing

Since stainless steel is an ideal metal for sanitization, corrosion resistance, and is not prone to rust, it is well suited for thousands of different uses! To demonstrate just how versatile it can be, we will explore how many ways it can be used in just one type of facility in a single industry; a hospital. Within a hospital, stainless steel tubing of all sizes is used for countless integral processes and operations. The structure of the hospital itself would use stainless steel tube in the form of pipes, ventilation, and drainage, as well as parts of electric wiring components. Within the hospital, large stainless steel tubes can be cut and formed for use as hazardous waste and chemical containers. On a much smaller scale, stainless steel tube can be found in all different types of medical equipment and devices. In fact, stainless steel 304 is the most common material used in medical devices, since it offers antibacterial properties, ease of cleaning, and resistance to corrosion or reaction to bodily fluids. For these reasons, one of stainless steel tube's most important applications is its use as hypodermic tubing for needles and intravenous devices. Modern hospitals simply couldn't function without lots and lots of stainless steel tubing!

Tubing applications in every industry

Just considering some of the many uses for stainless steel tubing within a single facility in only one industry demonstrates just how many ways this versatile, customizable product can be used. To fully grasp how integral stainless steel tubing is to our lives, it's important to consider that it has numerous uses in our homes, including within our appliances, water, heating, and plumbing systems, in our cars, and in the tools we use. Outside of our homes, stainless steel tube plays a role in nearly every industry we rely on, from food and beverage processing to transportation, construction, technology, automotive, and more. Since stainless steel tube can also be formed in square and rectangular configurations, the number of potential uses increase even further. New uses are being found for stainless steel tube every day, and as innovators develop ways to incorporate it in products and inventions, our lives are improved in many ways – some small, and others monumental.

Why Choose Stainless Steel For Ornamental Tube Products

Ornamental tubing is an essential element of a wide range of products spanning an equally vast range of industries.

While its name might suggest that it's just for looks, often ornamental tubing is a critical component in the safety and operation of the environments or equipment on which it is used.

Where is stainless steel ornamental tubing used?

Ornamental tubing is a very common product. You have likely interacted with a piece of it already at some point today.

Common uses for ornamental tubing include:

Grab bars in washrooms

Handrails for hallways or steps

Handrails for elevators

Running or step boards on vehicles

Handles for ovens, refrigerators, and other restaurant equipment

Swimming pool rails and ladders

Boat rails and ladders

Exercise equipment

Medical equipment

Whether you're at work or at home, there's likely a piece of ornamental tubing just steps away!

Why use ornamental stainless steel tubing in your design?

In general, you'd use stainless steel ornamental tubing for the same reasons you'd use any stainless steel product.

The biggest concern in most cases is corrosion resistance. Stainless steel's passive layer means you don't have to worry about corrosion and degradation in moist or acidic environments.

However, easy maintenance is also a primary consideration in many cases.

The same passive layer and smooth finish, which help protect stainless steel from corrosion, also provide straightforward maintenance and cleanup.

In most cases, the only supplies needed to keep stainless steel looking great are warm water, mild soap, and a soft cloth.

However, stainless also works with a wide range of cleaners and can even be sprayed off in many cases allowing for flexible maintenance in various settings.

Finally, stainless is strong and long-lasting. Whether you're using it for handles, handrails, structural elements, or ladder rails, the weakest point on many stainless steel ornamental tubing installations isn't the tube but the mount itself!

Combine all of these traits with affordable pricing, ample supply, and near-endless customization options, and it's easy to see why this type of tubing is so popular across a range of industries and implementations.

What to consider when choosing stainless steel ornamental tubing?

Like choosing any stainless steel piping product, understanding the various characteristics and options available is essential for finding the ideal part for your project or design.

In this section, we'll look at things you should consider.

The priority of each consideration will largely depend on your individual goals and requirements, so while we'll present them in a specific order, feel free to weigh one consideration heavier than others as it applies to your situation.

- Disclaimer: All choices should be made with the assistance of a qualified professional. The following information is intended as a high-level overview of the options available. You should not take it as purchasing recommendations without first consulting an engineer or other qualified party to assess your exact needs and requirements.

Ornamental tube shapes and sizing

One of the most obvious ways to differentiate stainless steel ornamental tubing is its shape.

Typically, the tubing is available in round, square, or rectangular shapes.

Multiple shape options allow you to match the tubing to both the visual style and the intended function of the final product.

Rectangle stainless steel tubing, for example, might serve well as a load-bearing surface for ladders or as a storage or shelving component.

Round tubing will provide a comfortable and reliable grip for elements such as grab bars or handles.

But shape will also influence the size of tubing available.

For example, within each of these shapes, Unified Alloys offers the following sizes:

Round tubing is available in outer diameters ranging from 0.5- to 6-inches.

Square stainless steel tubing is available in outer diameters ranging from 0.5- to 8-inches.

Rectangular tubing is available in sizes ranging from 0.5-inches-by-1-inch to 0.5-inches-by-12-inches.

Choosing the ideal grade of stainless steel

In most cases, stainless steel tubing is available in two grades: 304/304L and 316/316L. 304/304L is the most popular grade of stainless steel in use today.

So which should you choose?

Again, it depends on your intended use.

In many cases, the primary determining factor will be the need for additional corrosion resistance against chlorides and acids.

If you're looking to use the stainless steel ornamental tubing in corrosive environments–such as food processing, breweries, paper and pulp processing, oil and gas processing, medical and pharmaceutical settings, chemical processing, or maritime applications–the enhanced corrosion resistance offered by 316/316L ornamental tubing will be well worth the additional cost.

However, for more decorative applications in less corrosive environments–such as automotive trim, residential kitchen equipment, or appliances–304/304L ornamental tubing offers excellent corrosion resistance for light-to-moderate uses at a more affordable price point.

For more information on how these two common stainless steel grades compare, consult our guide, "304 vs 316 Stainless Steel: What You Need to Know."

Putting a final touch on your selection with finishes

Finally, within each tubing size and shape, you'll find a variety of stainless steel finishes.

The ideal finish will depend on your application, but the most common finishes for ornamental tubing are:

- Mill Finish: Keeping the standard mill finish saves money while allowing you to apply a finish yourself to suit your exact requirements. This can also provide you with the opportunity to fabricate or weld using stainless steel tubing without the worry of marring the finish.

- 180 Grit: Capable of producing a range of finishes, 180 grit is typically used in coarse, brushed, architectural, dairy, or sanitary finishes. These generally are smoother than mill finishes without the bright, mirror-like finish of higher grits. These finishes are typically used when an item will see frequent use as it provides an optimal balance of visual appeal, corrosion resistance, and easy cleaning.

- 600 Grit: Often used with decorative tubing and trim, these high-grit finishes provide an ultra-smooth surface with a bright finish and clear reflections similar to chrome or a mirror. However, the finish is typically more expensive and will require more delicate upkeep to avoid fingerprints and smudges.

Things to Know About 316 Stainless Steel Round

According to the definition, stainless steel is an iron alloy that contains a minimum of 10.5% chromium. There's an incredible variety of the sorts of alloys available on the market, and they each differ in their exact chemical makeup. Alloying elements like nickel, molybdenum, titanium, carbon, nitrogen, and copper can increase the strength, formability, and other properties of stainless steel.

To qualify as stainless steel, it must meet guidelines for corrosion resistance in an exceedingly specific environment. This resistance arises from the metal's chromium oxide outer layer.

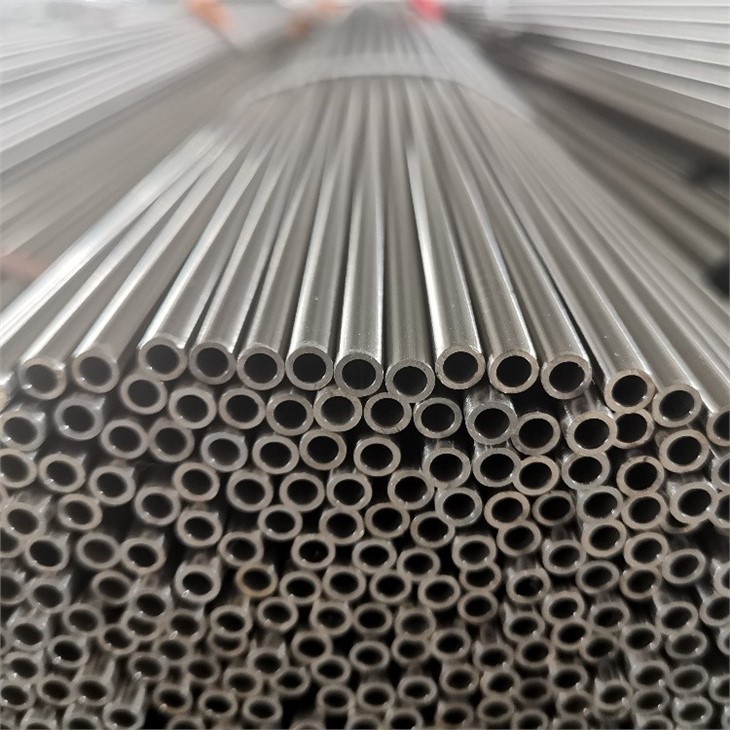

Stainless Steel Round Tubes

Welded stainless steel tubes in Cuttack are created by forming sheets of steel during a tube shape and then welding the seam. Both hot-formed and cold-formed processes are used to create stainless tubing, with the cold process producing a smooth finish and tighter tolerances than hot-forming. Both processes create a steel tube that resists corrosion and features high strength and firmness.

Stainless steel is additionally easily cleaned and sterilized and may be easily welded, machined, or bent to make a line. This mix of things makes stainless-steel tubing a superb choice for structural applications, especially those where the tubes could also be exposed to corrosive environments.

The terms "tube" and "pipe" are frequently used interchangeably, but there are important differences between the two. While they share an identical hollowed shape, steel tubes are measured by their outside diameter (OD) and wall thickness, while steel pipes are measured by their inside diameter (ID). Another difference is that steel tubes are used for structural or aesthetic applications, while pipes are commonly used for the transport of gases and fluids.

Choosing Between 304 Stainless Steel And 316 Stainless Steel Round Tubes

300-series-grade steel is produced in a range of products, including steel tubes, steel pipes, and various other products. 304 and 316 steel tubes are nickel-based alloys that are low-maintenance, corrosion-resistant, maintain toughness, and are long-lasting at high temperatures. Identifying which grade of steel is good for an application depends on the planned application as well as environmental factors such as temperature or exposure to chloride.

304 stainless steel is corrosion-resistant and easy to cleanse or purify, making it the most common type of stainless steel used for tubing and other steel parts. 304 has been mostly used for building and decorating applications.

316 is commonly similar to 304 stainless steel, is also corrosion-resistant, and is easy to cleanse and purify.

316 stainless steel is more corrosion-resistant, which is caused by chloride, chemicals, and solvents. This additional factor of 316 stainless steel is a good solution for applications which is constantly exposed to chemicals or for outdoor applications where there is exposure to salt.

Applications Of 316 Stainless Steel Round Tubes Are Used In The Surgical Industry And Marine Industry.

Advantages of Stainless steel for tubing applications

Stainless steel is widely used because of its toughness, corrosion resistance, and beautiful appeal. Varieties of benefits include:

• Durability

• Long-lasting

• Better Corrosion-resistant

• Easy to purify

• Light-weight

• Maintenance is low.

• Handles high flow rates.

• Scratch-proof materials.

• Reusable, recyclable, and environmentally friendly material.

Applications of stainless steel pipes include:

• Food processing industry

• Textile industry and operations

• Water treatment plants

• Oil and gas processing industry

• Construction Industry

• Chemical Industry

• Pharmaceutical industry

• And used in the automotive industry

Our Factory

With a vast stock holding of stainless steel sheets, coils, strips, tubes, and bars, we have a wide range of products readily available to meet your immediate needs. Our comprehensive inventory ensures quick access to the materials you require.

FAQ

Hot Tags: stainless steel round tube, China stainless steel round tube manufacturers, suppliers, factory

You Might Also Like